This study provides various implications that create sustainable development in the manufacturing industry for the transition to additive manufacturing.

Authors

Sachin Kumar Mangla, Full Professor and Director, Research Center for Digital Circular Economy for Sustainable Development Goals (DCE-SDG), Jindal Global Business School, O.P. Jindal Global University, Haryana, India.

Neslihan Top, Faculty of Technology, Industrial Design Engineering Department, Gazi University, Ankara, Turkey.

Ismail Sahin, Faculty of Technology, Industrial Design Engineering Department, Gazi University, Ankara, Turkey.

Muruvvet Deniz Sezer, Faculty of Business, Business Administration Department, Yasar University, İzmir, Turkey.

Yigit Kazancoglu, Faculty of Business, Department of Logistics Management, Yasar University, İzmir, Turkey.

Summary

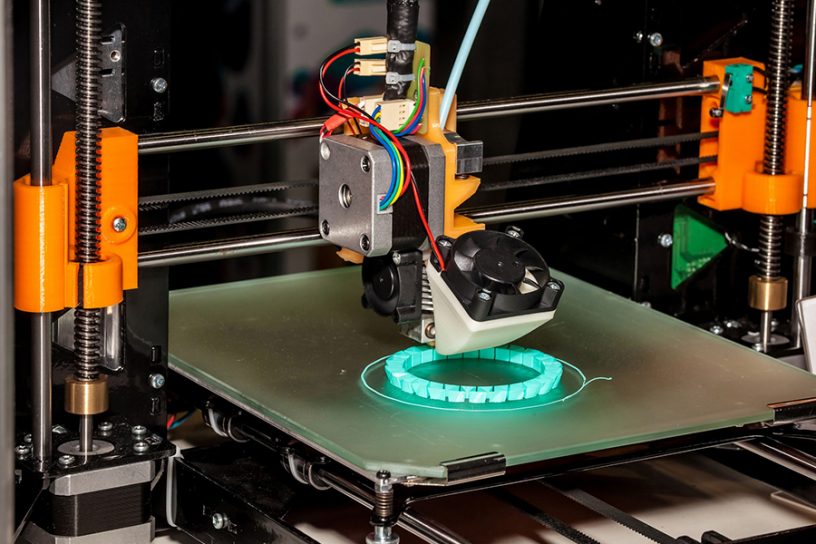

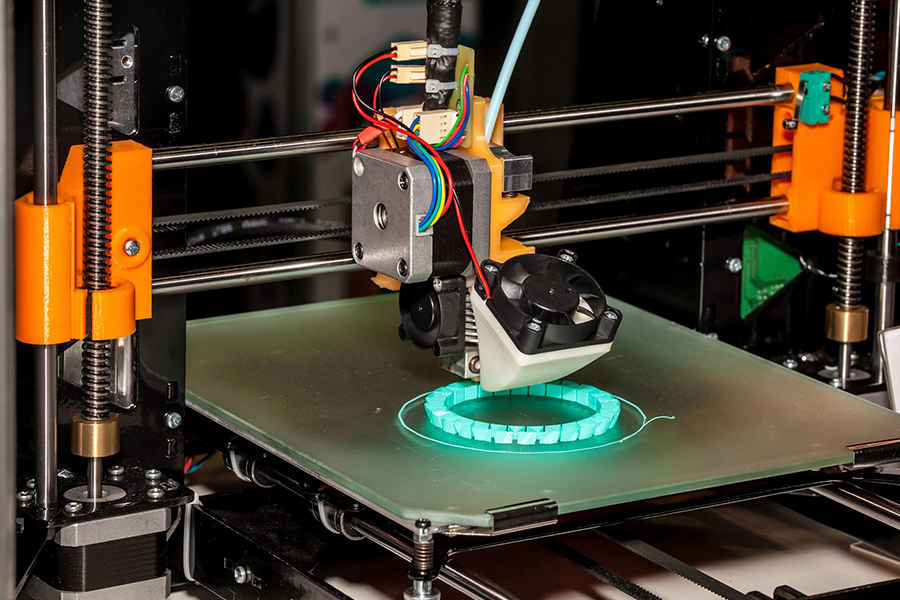

Additive Manufacturing (AM) has emerged as an important digital technology in improving production efficiency by analysing possible environmental impacts of the operations. Therefore, this study aims to investigate the impacts of redesigned products for transition to AM on sustainable production processes. In this study, an industrial-scale product was redesigned according to AM principles and manufactured using the Fused Deposition Modelling (FDM) technique.

The environmental impacts of the production methods were evaluated in terms of material consumption and carbon dioxide (CO2) emissions using the Life Cycle Assessment (LCA) method. Thus, according to LCA results, the use of a single type of material and production method for the redesigned product, as well as reducing the amount of material used by eliminating the fasteners, resulted in a 60.45% reduction in material consumption and 85.59% reduction in CO2 emissions compared to CM.

Although the production time in CM is shorter than FDM, the necessity of a mould design and manufacture by pre-processing resulted in an increase in delivery time. Results show that the material unit costs for both manufacturing methods are very similar. This study provides various implications that create sustainable development in the manufacturing industry for the transition to AM.

Published in: International Journal of Production Research

To read the full article, please click here.